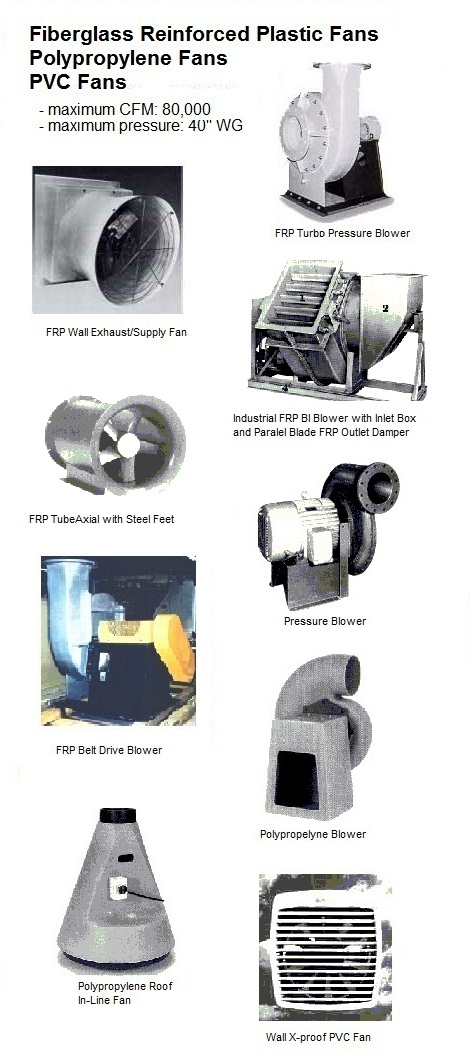

Many processing plants including water and waste water treatment plants require rugged, corrosion resistant equipment designed for many years of reliable use. Fans & blowers are subjected to both harsh chemicals and continuous duty applications, including odor control, air strippers, sludge drying, aeration and HVAC for building comfort. We provide Fiberglass Reinforced Plastic (FRP) fans that are resistant to many corrosive agents including hydrogen sulfide and sulfur dioxide, commonly found in waste water plants.

Canada Blower Typical Fans Applications:

– Odor Control

– Scrubber Fans

– Air Stripper Fans

– General Ventilation

When it comes to Fiber Reinforced Plastic fans or FRP blowers, there are several key benefits. Because of that, these fans are ideal for both industrial and commercial applications.

Canada Blower

http://chicagoblowercanada.com/airfoilblower.html

http://chicagoblowercanada.com/axialfan.html

http://chicagoblowercanada.com/backwardcurvedblower.html

http://chicagoblowercanada.com/biblower.html

http://chicagoblowercanada.com/centrifugalfan.html

http://chicagoblowercanada.com/coils.html

http://chicagoblowercanada.com/ductfan.html

http://chicagoblowercanada.com/ductfans.html

http://chicagoblowercanada.com/fanaccessories.html

http://chicagoblowercanada.com/forwardcurvedfans.html

http://chicagoblowercanada.com/frpfans.html

http://chicagoblowercanada.com/hoodedfans.html

http://chicagoblowercanada.com/index.html

http://chicagoblowercanada.com/MakeUpAirFans.html

http://chicagoblowercanada.com/mixflowfans.html

http://chicagoblowercanada.com/oemfans.html

http://chicagoblowercanada.com/pressureblower.html

http://chicagoblowercanada.com/propellerfans.html

http://chicagoblowercanada.com/radialblower.html"

http://chicagoblowercanada.com/rfq.html

http://chicagoblowercanada.com/roofcentrifugalfans.html

http://chicagoblowercanada.com/rooffan.html

http://chicagoblowercanada.com/rooffans.html

http://chicagoblowercanada.com/tubeaxial.html

http://chicagoblowercanada.com/tubeaxialfan.html

http://chicagoblowercanada.com/upblastfans.html

http://chicagoblowercanada.com/vaneaxial.html

http://chicagoblowercanada.com/wallfans.html

Replacement Twin City Fans / TCF

blowers and Aerovent ventilators, Chicago Blower fans, industrial

pedestal ventilators, in line fans, confined space fans, in-line

exhaust blowers, radial blade fans, paddle wheel ventilators, hvac

blowers, high temperature pressure blowers, fiberglass ventilators,

stainless steel fan blowers, material handling radial blowers, blowoff

fans, direct drive blowers, belt drive fans, air vent fans. Supplier of

radial blowers, vaneaxial & tubeaxial ventilators, explosion proof

spark-resistant fans, fiberglass FRP, PVC and Propylene blowers, oven

circulating super high temperature fans. Suppliers of industrial

process fans and blowers.

Centrifugal and axial air handling fans, blowers, ventilators; belt and

direct drive fans; single-width and double-width blowers; Airfoil fans;

Pressure Blowers.

Sales of New York Blower fans and blowers: high pressure fans, high

temperature blowers, general ventilation utility fans, centrifugal and

axial fans anv ventilators. Air fans, blowers and ventilators for

industrial plants from Buffalo, New York. Sales of industrial axial

power roof and wall ventilators, exhaust and supply centrifugal spun

aluminum fans and blowers.

scroll

centrifugal and axial Buffalo Blower air handling fans and ventilators;

belt

and direct driven Buffalo fan ventilators; single-width and

double-width blower

fans; radial blowers; induce draft and force draft Buffalo Blower fans;

high

pressure and high temperature pressure blowers.

Type AF Power

Roof Ventilators utilize vaneaxial and tubeaxial fans to which a

separate damper head and curb sheet are attached. Their construction

incorporates flanged wind band, or shroud with rain gutter, supplied

with integrated gravity automatic dampers pivoted in bushing bearings,

dampers stops and flange, tube-axial, or vane-axial fan stack,

available in direct drive - arrangement 4, or belt drive with belt

tension adjustment arrangement 9 configuartion, motor cover, or belt

gurad, gussets, heavy duty fan wheel, available with a variety of

motors, corrosion an dmoisture resistant finishes.

Canadian Blower PRV Power Roof ventilators provide clear evidence of

the continued leadership of Canadian Blower in the engineering

development and manufacture of ventilating fan packages for industrial

and commercial ventilation. Canadian Blower Company axial roof fans

cover sizes ranging from 15" to 84" wheel diameters with capacities

from 2000 CFM to 200,000 CFM.

PRV Power Roof Ventilators is a low-silhouette, factory assembled

package unit constructed to withstand hurricane force winds. It

construction incorporates galvanized steel wind band, rain gutter,

automatic dampers (gravity action) with damper bearings and damper

stops, optional stack for true vertical discharge, gussets to fasten

the wind band to the stack, streanlined die formed Venturi closely

shrouding fan prop/wheel, heavy duty prop supplied in variety of

designs, roof curb sheet with flanged edges, totally enclosed air over

high efficiency motors, special coatings for corrosion and moisture

resistance. This type of power roof ventilator is available in Tilt-Up

construction, which provides access to drives and motors direct from

the roof.

FRP Construction - Fiber Reinforced Polyester corrosion resistant

construction is available for all up-blast power roof ventilators along

with protective coatings for corrosive exhaust fumes or atmosphere

including synthetic vinyl plastic and a cathalytic epoxy coatings.

Corrosion resistant construction and chemical duty construction: for

corrosive environment wall fans are avaialble in 304 SS, 316 SS, or 316

L stainless steel construction.

Emergency Duty Purge Up-Blast Ventilators incorporate elements of

sealed and high-temp. consturuction for emergency fume and smoke

exhaust.

The versatile Canada Blower fiberglass reinforced plastic (FRP) fan is

offered in all three fan impeller designs and in sizes to fit all

commonly used duct diameters. While fan arrangement 9 is considered

standard, arrangements 1, 4 and 8 are available on most series and

sizes to better suit the specific installation. In addition to a

multitude of standard fan models, custom Canada Blower fans can be

fabricated to meet unique requirements, including alternate plastic

resin formulations and exotic metal high-pressure blower impellers.

From steel mills to chemical processing to emissions control, today's

industrial air moving and exhausting systems must withstand a growing

variety of severe corrosives. Canada Blower's fiberglass reinforced

plastic (FRP) fans are built to handle these harsh fumes, vapors and

gases. Canada Blower fiberglass polyester composition is also

impervious to extreme outside environments. Exterior steel components

are protected by a special vinyl phenolic coating.