Buffalo Up-Blast Power Roof Ventilators

Buffalo

Style V Sky-Vent Power Roof ventilators provide clear evidence of the

continued leadership of Buffalo Fan in the engineering development and

manufacture of ventilating fan packages for industrial and commercial

ventilation. Buffalo Fan Company incorporated BREEZOs design T,

Design 53 Belt-Airs, Design 80, Design 65 and Design 50 NV fans, Type B

fans, including LB, MB, HB pitched props, Types K and Type F fans

Design T, AEROPROP design 53 and Design C, Type K, Type F fan

components covering size ranging from 15" to 72" wheel diameters with

capacities from 2200 CFM to 130,000 CFM.

Canada Blower Up-Blast Roof

Exhausters is the most economical way to arrange roof exhaust from

industrial manufacturing facilities and large warehouses:

- Heavy-duty reliable industrial ventilator construction;

- Cast aluminum efficient propeller;

- Galvanized steel hood and ventilator base;

- Fibergalss butterfly fan dampers serve as a skylight;

- Belt driven ventilator models for flexibility or direct driven fan

models for low maintenance;

- Available Canada Blower fan accessories include: outlet guard, auto

heat & smoke trip, magnetic latches, special protective coatings,

bird screen, disconnect switch, roof curb ...

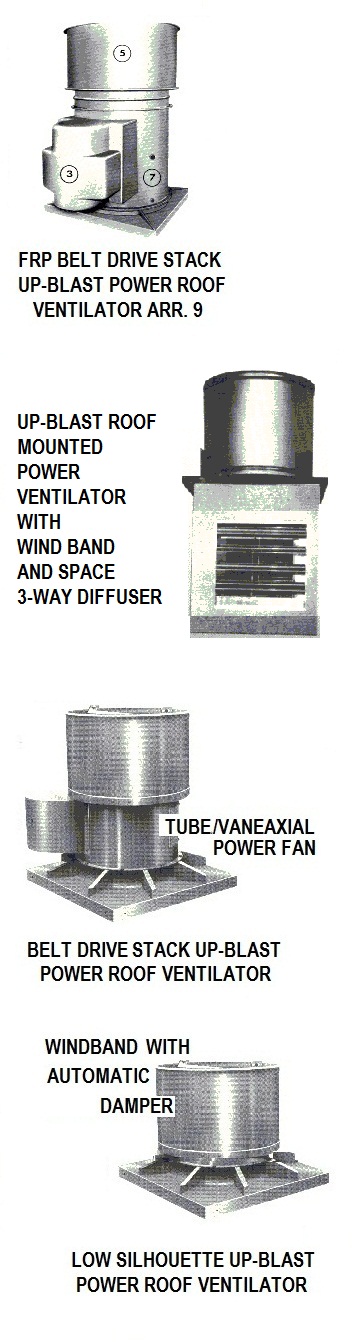

Style V So-Low Sky-Vent Power Roof Ventilators is a low-silhouette, factory assembled package unit constructed to withstand hurricane force winds. It construction incorporates galvanized steel wind band, rain gutter, automatic dampers (gravity action) with damper bearings and damper stops, optional stack for true vertical discharge, gussets to fasten the wind band to the stack, streanlined die formed Venturi closely shrouding fan propeller / wheel, heavy duty prop supplied in variety of designs, roof curb sheet with flanged edges, totally enclosed air over high efficiency motors, special coatings for corrosion and moisture resistance. This type of power roof ventilator is available in Tilt-Up construction, which provides access to drives and motors direct from the roof.

AF Type Style V Sky-Vent Power Roof Ventilators utilize vaneaxial and tubeaxial fans to which a separate damper head and curb sheet are attched. Their construction incorporates flanged wind band, or shroud with rain gutter, supplied with integrated gravity automatic dampers pivoted in bushing bearings, dampers stops and flange, tube-axial, or vane-axial fan stack, available in direct drive - arrangement 4, or belt drive with belt tension adjustment arrangement 9 configuartion, motor cover, or belt gurad, gussets, heavy duty fan wheel, available with a variety of motors, corrosion an dmoisture resistant finishes.

FRP Fan Construction - Fiber Reinforced Polyester corrosion resistant construction is available for all up-blast power roof ventilators along with protective coatings for corrosive exhaust fumes or atmosphere including synthetic vinyl plastic and a cathalytic epoxy coatings.

Corrosion resistant fan construction and chemical duty construction: for corrosive environment wall fans are avaialble in 304 SS, 316 SS, or 316 L stainless steel construction.

Emergency Duty Purge

Up-Blast Ventilators incorporate

elements of sealed and high-temp. consturuction for emergency fume and

smoke exhaust.

Manufacturer of I.D. blowers, F.D. blowers, force draft fans, force draft blowers, blow off ventilators / fans, PVC FRP SST ventilators, squirrel cage blower fans, high pressure centrifugal ventilators, Chicago blowers, aluminum fans, stainless steel ventilators, hot air blowers, heating fans, high temperature oven ventilators, high pressure air blowers, squirrel cage blower wheels, Peerless Dayton ventilators, Sheldons blowers, New York fans NYB, TCF, Delhi fans blowers. Pressure blowers; plug fans; air kits; centrifugal and axial ventilators.

Engineers of alloy pressure blowers, pressure blowers with high temperature construction, stainless steel, aluminum, and fabricated steel construction. Supply of replacement centrifugal fans, centrifugal blowers, and parts for centrifugal fans, and centrifugal blowers manufactured by Buffalo Blower in New York, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian Blower, Howden Buffalo, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Breidert, Anderson 2000, Solar & Palau, Strobic air, Trane, TCF Axial, Aerovent.

Canada Blower Company is a supplier of Industrial and Commercial fans and blowers of all types.

Canada Blower Ventilation Sets:

Canada Blower Company is a major Industrial and OEM fan and blower manufacturer in North America. Chicago Blower Fans are well know for their highest manufacturing quality, reliability and industrial toughness for many years across the world.

Canada Blower PT Air Make-Up System has the following advantages over coventional make-up air units:

* Offers savings in initial investment and operating costs;

* Provides draft-free and uniform air distribution from along tube rather than blasting air from a single source outlet;

* Uses less energy due to lower horsepower for the same supplied air volume and because of friction loss of blowing air through a heat transfer system is completely eliminated;

* Easier and less costly to install, as PT Fan system is relatively light in weight ans the polyethylene tubing can be installed in a fraction of time normally required for conventional ventilation ducts;

* Eliminates coil freeze-up problems typical for AHU with heating hot water and steam heat exchangers;

* Reclaims overhead heat wasted in most buildings - through mixing of outside air with inside hot air;

* Very quiet, normally within 20 Fan Sones;

* Flexible in capacity, which is achieved by running only the required number of PT units based on the temperature inside the building;

* Provides a more comfortable eworking environment by maintaining gentle air flow and uniform temperature distribution.

Power Tube Make-Up Air Fans are available in Sizes 18 to 48 for for air flows up to 40,000 CFM.

PT Power Tube Make-Up Air System tube is constructed of thick woven high density polyethylene fiber(8 x 8) laminated with poly coating to a thickness of 6 Mils. It is 3.8 oz. per square yeard material. Burst strength is 118 Lbs per square inch. The material is flame retardant and complied with NFPA Standard 701. Tubes are available in two colors: blue and white. One end of the polyethylen tube is factory dealed.

Sufficient make-up air should be provided to balance exhaust from general ventilation and process ventilation. Usually several Power Tube Fans will be required, located to distribute air throughout the plant. If additional tempering of make-up air in specific plant areas becomes necessary, unit heaters can be added..

.