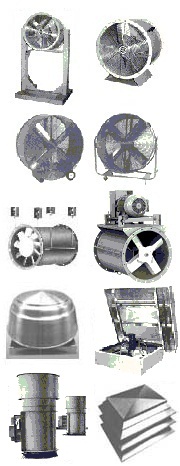

HEAVY DUTY AXIAL FANS

When most people hear the word

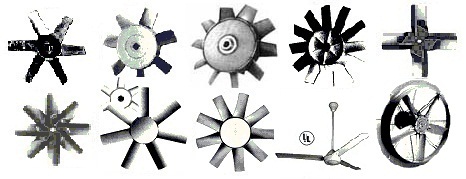

“fan”, they generally imagine axial fans. Axial fans contain blades

that extend radially from a central hub. As the blades spin, they draw

in and force out air along an axis parallel to the axis of rotation.

The basic design of Canada Blower axial fans allows them to produce

airflow with a high flow rate and low pressure, meaning they are

generally suitable for applications that simply require moving large

volumes of air from one space to another. However, the exact design and

configuration of a fan may vary depending on the particular

requirements and restrictions of the intended application.

Canada Blower offers the following types of axial fans:

Tubeaxial

Vaneaxial

Propeller

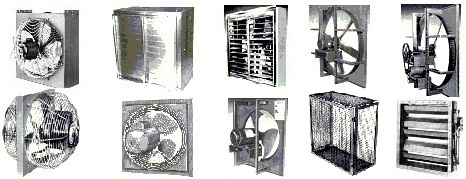

Roof Supply & Exhaust

Wall Supply & Exhaust

Duct Inline

Mixed Flow

Smoke & Heat Removal

Adjustable Pitch

Anti-Stall

Direct & Belt Drive

Canada Blower Heavy Duty Axial fans are available available in three basic designs: types AP N and AN N are power plant axial fans designed for larger fossil fuel boilers, especially when reduced load requirements will be encountered. Type MA Adjustax-able axial fans are designed to deliver high capacities (to 900,000 cfm) and medium to high pressures (to 20" total pressure in single stage, to 40" total pressure in two stage) for a variety of industrial process and ventilation applications.

Canada Blower duct fans, tubeaxial fans, vaneaxial fans, roof ventilators and wall propeller fans are found throughout the world operating in industrial processes where performance, reliability and maintainability are of paramount importance. Ranging in diameter from 6 inches to over 9.3m, and with a variety of impeller designs, control systems and layout options, they form a comprehensive series of axial fans to satisfy virtually all industrial applications. The majority of the fans we supply can be grouped into four broad categories: with fixed pitch props, with variable pitch props, with mixed flow props, and two stage props. All are supplied to the same exacting standards, capable of moving from a few hundred cubic feet per minute, to heavy duty adjustable pitch props with capacities up to 900,000 CFM and with static pressures from 0 " Water Gauge (WG) to 40" " WG.

Canada Blower axial flow fans are best buy for many industrial air moving jobs. Generally, an axial ventilator costs considerable less than a quality centrifugal fan delivering the same volume and pressure. They cost less to install since they are lighter, requiring minimum structural support. They can be duct mounted, taking up little space. Direct drive fan models mean faster start-up and the abscence of V-belt drive and fan bearings lowers maintenance costs.

Adjustax-able VaneAxials feature an adjustable pitch blade fan wheel that permits matching your pressure/volume requirements exactly, and lets you make on-the-job adjustments to compensate for system changes.

Type B Axilas have fixed ventilator blade wheels in capacities up to 300,000 cfm and to 5" total pressure.

The Aeroline swing-out fans are efficient low moise level fans where the entire rotating assembly swings out for maintenance.

Canada Blower

http://www.industrialfanblower.com/index.html

http://www.industrialfanblower.com/axialfan.html

http://www.industrialfanblower.com/centrifugalblowers.html

http://www.industrialfanblower.com/dustcollectionblower.html

http://www.industrialfanblower.com/exhaustblower.html

http://www.industrialfanblower.com/feedback.html

http://www.industrialfanblower.com/furnaceblower.html

http://www.industrialfanblower.com/idfan.html

http://www.industrialfanblower.com/paintshopblower.html

http://www.industrialfanblower.com/sitemap.html

Stock of tubeaxial & vaneaxial inline duct fans, blower and fan repair / balancing, replacement centrifugal and axial fan blades, axial duct fans, aluminum pressure blowers, FRP ventilators, dust collectors blowers fans, dust collection fan ventilators, high temperature oven circulation fans, explosion proof ventilatoprs, spark reistant fans and blowers, induce & force draft fans, fan blower impellers. Custom fans, heat resistant fans, panel fans, suction fans, up-blast and down-blast fans and blowers, vaneaxial, tubeaxial, tubular acoustafoil fans.Industrial process and O.E.M. fan blower ventilation equipment; sales of high pressure blowers and high temperature oven exhaust fans; oven circulation fan air-kits; material handling radial blower fans.

Canada Blower is a major Industrial and OEM fan and blower manufacturer in North America. Canada Blower fans are well know for their highest manufacturing quality, reliability and industrial toughness for many years across the world.

Fiberglass (FRP) axial and centrifugal fans are designed for corrosive air stream applications in which metal fans will not withstand hostile environments or aggressive conditions. FRP fans operate in corrosive applications with high efficiency and low noise characteristics. Examples of FRP plastic fan applications include the chemical processing industry, waste water treatment plants and analytical laboratories.

A variety of plastics, including polypropylene and PVC, are employed to manufacture a host of industrial equipment, including plastic fans and blowers for corrosive applications and environments, across a wide span of industries. Canadian Blower Co. plastic fans provide the benefits of:

- Ease of maintenance

- Cost efficiency

- Low noise

- Efficient operation

- Rugged durability

- Maximum corrosion resistance

Canadian Blower Co. understands industrial exhaust fan technology and works with the leading industrial exhaust fan manufacturers to manufacture the best fan / blower equipment.

PVC Fans Polyvinyl chloride, or PVC, is a thermoplastic polymer that is inexpensive and able to withstand a broad range of corrosive applications. PVC fans are an excellent choice for the efficient conveyance of corrosive, humid, or polluted gases, fumes and air. Fire-retardant and corrosion resistant, PVC fans are specially suited for hostile environments in which coated metal usually corrodes. Typical applications are steel pickling, chrome plating, battery manufacture, and pharmaceutical lab exhaust.

In corrosive environments, where corrosive elements occur in the form of fumes or vapors, fiberglass or other plastic construction is recommended. Canadian Blower Co. offers a wide selection of products for any corrosive application, featuring the benefits of:

- Time-tested quality

- Reliable performance

- Long-lasting durability

Canadian Blower Co. plastic fans are constructed of FRP, PVC, CPVC, polypropylene, Kynar and are selected based on temperature and air stream chemistry. FRP fans are an excellent choice for corrosive environments. The construction is lightweight, yet extremely strong for a long service life. Fiberglass nyb fans feature the benefits of:

* Solid FRP housings

* Standard with UV inhibitor and flame retardant resin

* Encapsulated hardware in airstream

* The only fiberglass wheel in a solid, one-piece design (die formed in molds)

* Fans conform to ASTM D4167-97

Complementing the Industrial Pressure Blower Co. FRP fans is a complete package of FRP air control products