Buffalo Power Roof Ventilators and Make-Up Air Fan Heaters

Buffalo Style H Sky-Vent Power Roof ventilators provide clear evidence of the continued leadership of Buffalo in the engineering development and manufacture of ventilating fan packages for industrial and commercial ventilation. Buffalo Forge Company incorporated BREEZOs design T, Design 53 Belt-Airs, Design 80, Design 65 and Design 50 NV fans, Type B fans, including LB, MB, HB pitched props, Types K and Type F fans Design T, AEROPROP design 53 and Design C, Type K, Type F fan components covering sizea ranging from 12" to 120" wheel diameters with capacities from 2200 CFM to 210,000 CFM, and heating capacity up to 4,500,000 BTU/hr.

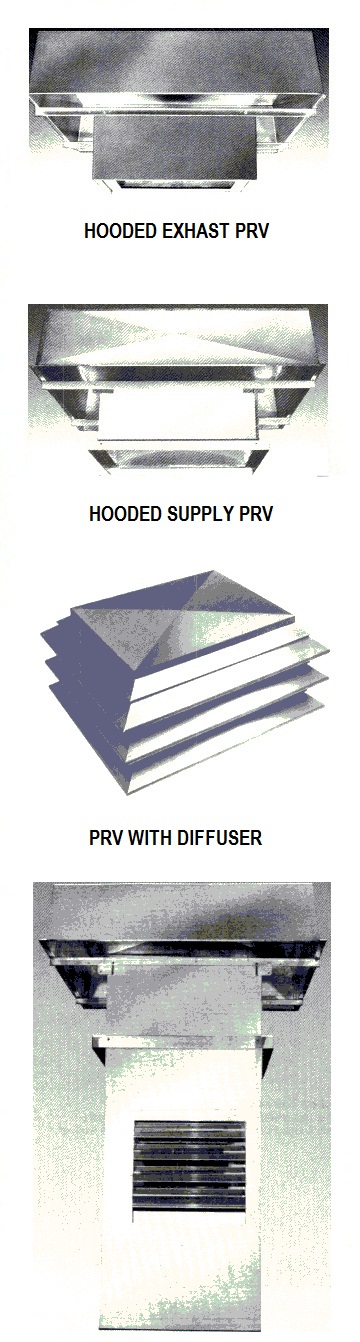

Style H Sky-Vent Exhaust Power Roof Ventilator is a factory assembled package fan unit constructed to withstand hurricane winds. Its construction incorporates mushroom head, or hood head with bird screen, which is hinged to a box-style stack, supplied with access door. For higher capacities stack can be substituted with tubeaxial, or vaneaxial fan. Curb caps are welded to the curb side of the stack. Fan panel assembly is located near the top. Back-draft stack dampers are standard option. Disconnect safety switch is mandatory for roof mounted units.

Style H Sky-Vent Supply Power Roof Ventilators are supplied with optional filter rack and filter package protected by bird and insect screen. Motorized back draft dampers are standard on all supply air fans. Filtered mushroom head features channel type filter racks, bird screen, hinged connection to the stack box. Special coatings are available upon request. Fan panel is of double orifice design to allow for supply/exhaust, or reverse-flow operation. Discharge diffusers are available in variety of styles.

Style H Sky-Vent Make-Up Air Roof Ventilators are available with direct gas fired heater, or steam/hot water coil packages. Seven arangements are available for efficient control of the air flow in various modes on operation: fresh air /return air /by-passs air, in arrangements: A, B, C, D, E, G, and G.

FRP Fan Construction -

Fiber Reinforced Polyester corrosion resistant construction is

available for all hooded power roof ventilators along with protective

coatings for corrosive exhaust fumes, or atmosphere, including

synthetic vinyl plastic and cathalytic epoxy coatings. Canada Blower

FRV fiberglass roof ventilator is designed for roof mounted exhaust

applications where corrosion resistance is a primary consideration. The

standard Canada Blower FRP resin used for the FRV is resistant to a

large variety of alkalis and other chemical agents. When a corrosion

resistant fan is required to withstand chemicals that attack glass or

polyester resin, special plastic and reinforcing fan material can be

supplied.

Corrosion resistant

ventilator construction and chemical duty construction:

for corrosive environment all fans are avaialble in 304 SS, 316 SS, or

316 L stainless steel construction. Spark resistant construction is

available in all aluminum construction; wheels are made of special

alloys for non-sparking airtsream construction.

http://www.pressureblower.net/index.html

http://www.pressureblower.net/axial_fan.html

http://www.pressureblower.net/centrifugal_blowers.html

http://www.pressureblower.net/contact_us.html

http://www.pressureblower.net/products.html

http://www.pressureblower.net/root-blowers.html

Supply of HVAC fans and blowers, large fan ventilators, commercial ventilators & fans, portable blowers fnas, electric blowers & fans, heavy duty blowers, cooling ventilators, direct drive blowers, ventilation fans, multistage blowers, high volume ventilator fans, rotary lobe pressure blowers, fan / blower packages. New York Blower fans and blowers: high pressure fans, high temperature blowers, general ventilation utility fans, centrifugal and axial fans and ventilators. High capacity pressure blowers and custom made industrial fans and blowers. Sales of large induce and force draft centrifugal blowers and fans; exhaust and supply wall and roof ventilation fans; stainless; special alloy; FRP construction.

New York sales of industrial high pressure blowers and OEM venilating fans = from Buffalo, New York. Engineering of Canadian Blower / Chicago high temperature fans, process pressure blowers, regenerative pressure blowers; industrial; process and commercial heating; ventilating and air-conditioning HVAC. Industrial and Commercial Fans, Blowers and Ventilators, MakeUp Air Units, Louvers, Dampers, Heating/Cooling Coils, Humidifiers and Air Curtains. Supply of replacement industrial fans and industrial blowers, and parts for industrial fans, and industrial blowers, manufactured by Buffalo Blower / New York, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian blower, Aerovent, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Breidert, Anderson 2000, Solar and Palau, Strobic Air, Trane, TCF Axial.

Centrifugal / Radial fans offer regulated high pressure airflow that is required for several industrial applications and air pollution systems. Centrifugal fans are constant volume devices and can operate under high sensitive conditions such as high or low temperatures, corrosive gases, acidic fumes etc. There are several ways how a centrifugal fan can be used as a process fan in industries, such as in transporting air/gas, drying, cooling, material handling, air re-circulation etc.

Canada Blower Company is the engineering sales representative for Industrial and OEM fan and blower manufacturers in North America. Canada Blower fans are well know for their highest manufacturing quality, reliability and industrial toughness for many years across the world.

Canada Blower Single-Width Airfoil Centrifugal Fans are the most popular general ventilation fans because they fulfill most commercial general industrial air moving needs. With its energy efficient airfoil wheel, the Canada Blower SW-AF fans are ideal for clean air applications.

Canadian Blower supplies axial hooded fans covering sizea ranging from 12" to 120" wheel diameters with capacities from 2000 CFM to 200,000 CFM, and heating capacity up to 4,500,000 BTU/hr. Canadian Blower Axial Exhaust Power Roof Ventilators are factory assembled package units constructed to withstand hurricane winds. Its construction incorporates mushroom head, or hood head with bird screen, which is hinged to a box-style stack, supplied with access door. For higher capacities stack can be substituted with tubeaxial, or vaneaxial fan. Curb caps are welded to the curb side of the stack. Fan panel assembly is located near the top. Back-draft stack dampers are standard option. Disconnect safety switch is mandatory for roof mounted units.

Axial Supply Canadian Blower Hooded Power Roof Ventilators are offered with optional filter rack and filter package protected by bird and insect screen. Motorized back draft dampers are standard on all supply air fans. Filtered mushroom head features channel type filter racks, bird screen, hinged connection to the stack box. Special coatings are available upon request. Fan panel is of double orifice design to allow for supply / exhaust, or reverse-flow operation. Discharge diffusers are available in variety of styles.

PRV Canadian Blower Fan Power Roof Ventilators provide clear evidence of the continued leadership of Canadian Blower in the area of ventilating fan packages for industrial and commercial ventilation.

An exhaust fan is a mechanical ventilation device that helps to draw out stale and impure air from your home and bring in fresh air, thereby improving the quality of indoor air. Exhaust fans are typically ducted to the exteriors of your house, through which bad indoor air can effectively be removed from your living space.

Exhaust fans are very effective at any building ventilation. Without proper ventilation, the air inside your home can get filled with harmful contaminants and disease causing pathogens.

Canadian Blower Make-Up Air Roof Ventilators are available with direct gas fired heater, or steam / hot water coil packages. Seven arangements are available for efficient control of the air flow in various modes on operation: fresh air / return air / by-passs air, in various mounting arrangements.

FRP Construction - Fiber Reinforced Polyester corrosion resistant construction is available for all Canadian Blower hooded power roof ventilators along with protective coatings for corrosive exhaust fumes, or atmosphere, including synthetic vinyl plastic and cathalytic epoxy coatings.

Corrosion resistant construction and chemical duty construction: for corrosive environment all fans are avaialble in 304 SS, 316 SS, or 316 L stainless steel construction. Spark resistant construction is available in all aluminum construction; Canadian Blower wheels are made of special alloys for non-sparking airtsream construction.

Standard Buffalo fan / blower accessories include: flash / raised access door, inspection port, drain and plug, unitary base, shaft and bearing guard, belt guard, motor cover, spring vibration isolation, rubber-in-share (RIS) vibration isolation, vibrating pads, outlet damper, inlet vane damper, external inlet vane damper, evase, electrical / pneumatic actuators.

.