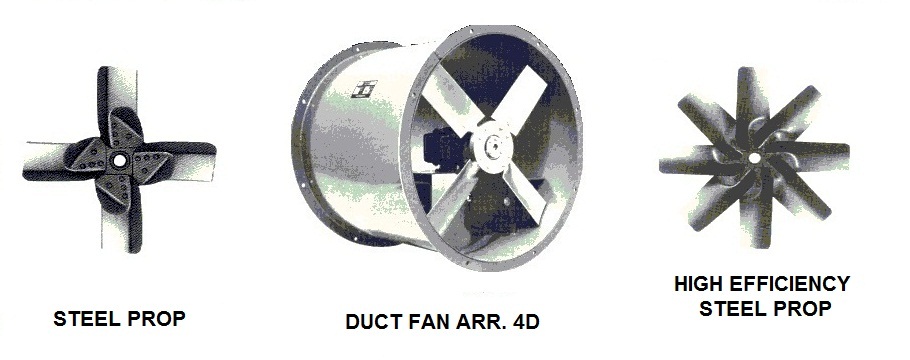

Canada Blower Duct TubeAxial and VaneAxial Fans

Canada Blower and Forge Duct

Tube Axial and Vane Axial Fans

for variable volume air handling applications utilize adjustable pitch

high efficiency aerofoil aluminum fan propellers to provide optimum

performance.

Buffalo Type VPS Adjustax Axial Fan have an internal blade pitch

adjustment,

which allows to bring variable air volume capability for air

conditioning, heating and ventilating applications.

All Canada Blower fan propellers and hubs are cast from 319 aluminum as standard. Ventilator propellers in sizes 12 through 72 inches are cast solid. Sizes 84 inches fans and larger are adjustable pitch with individual fan blades and hub. For specific applications such as high temperature environments (600°F, 315°C maximum), cast solid Canada Blower ventilator propellers are available in A240 aluminum alloy and, for corrosive environments, fan propellers are available in Dura-Metal (aluminum bronze, 500°F, 260°C maximum) alloy.

Clamshell Design Vaneaxial Fans are used primarily in applications where ready access to the interior of the fan is desired. The entire bearing assembly can be removed quickly and easily, without removing the fan from the stack. Heavy duty pillow block anti-friction bearings with split inner ventilator cylinder are standard. Clamshell design vaneaxial fans are avaiable with steel wheels and aluminum wheels.

Spray Booth Design Vaneaxial Fans are available in standard belt drive arrangement 9. These fans are designed for use in spraybooth installations, or in a variety of applications where requirements make it necessary to clean the fan periodically. Standard accessories include: inlet / outlet cones, inlet bell, screensfor fan, cone, or bell; belt guard, weather proof motor and drive cover, spark resitant construction with aluminum fan wheels, or steel wheels with bronze tipped blades; support legs, suspension clips, shaft seals are also available as standard fan options.

Spark Resistant X-proof construction on tubeaxial and vaneaxial fans is available in all aluminum airstream (AMCA A) construction; aluminum wheel (AMCA B) construction; and steel wheel with bronze tipped blades and shaft retainer (AMCA C) construction.

High temperature ventilator construction: upon request Buffalo vaneaxial fans can be furnished with optional high temperature construction for oven exhaust, or combusting gases exhaust applications.

Corrosion resistant

construction and chemical duty construction:

for corrosive environment all vaneaxial fans are available in FRP

construction, as well as in 304 SS, 316 SS, or 316 L stainless steel

construction. Special coatings are optional and selection is made based

on the application.

Canada Blower

Engineering sales of air knife

blowers, blow off fans, stainless steel fans and SST blowers, spark

resistant ventilators, combustion blowers, vane axial / tube axial

blowers, high pressure ventilators, sealed blowers and fans, FRP

fiberglass ventilators. Sale of wind tunnel fans, blast

blowers, direct drive fans and blowers, gas tight fans and blowers,

insulation

blowers and fans, Northern Blower Sales, Twin City fans.

Suppliers of industrial

regenerative side channel blowers, forward curved pressure blowers and

fans in stainless steel, alloy, cast aluminium, cast iron,

polypropylene and FRP construction. Canadian Blower, Chicago supplies

replacement forward curved blowers and wheels for forward curved

blowers and fans manufactured by Buffalo Blower - New York, Twin City

Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan,

Hartzell, IAP, Industrial air products, Canadian blower, Aerovent, Penn

Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair,

American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan,

Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson

Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo,

Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial

Air, Ceilcote, Breidert, Anderson 2000, Solar and Palau, Strobic air,

Trane, TCF Axial.

Canada Blower is a

major Industrial and OEM fan and blower supplier in North America.

Canada Blower fans are well know for their highest manufacturing

quality, reliability and industrial toughness for many years across the

world.

Positive Pressure Blower is a high volume fan use to pressurize a

burning structure, in case of fire, in order to force the smoke out.

Positive Pressure Blowers are portable, gasoline powered fans, most of

which utilize a 5.5 horsepower engine. The theory of positive pressure

ventilation is based on the principal of even pressure distribution.

Once a structure is pressurized, air and smoke can be forced out

through any opening (similar to escaping from an inflated baloon).

Electric smoke ejectors (negative pressure ventilation) can be used for

smoke removal but this has proven to be inferior to positive pressure

ventilation.

What makes Positive Pressure Ventilation superior to negative pressure ?

* The risk of injury from the engaged structure is reduced while

placing the fan in operation.

* Positive pressure ventilation is faster to set up and requires fewer

personnel.

* The Positive Pressure Blower has a self contained power source, while

electric fans require cords and adaptors.

* Smoke and heat is removed from all levels of the structure unlike

negative pressure which can result in localized extraction.

* Quicker results. After initial knockdown, positive pressure

ventilation can be initiated and will show immediate improvements in

the interior conditions.

* It allows replacement of contaminants with vital cooler, cleaner air

- especially in sealed or windowless buildings. It's also very

effective in large and compartmentalized buildings, warehouses,

schools, etc.

* Quick results allow firefighters faster entry due to lower heat

levels and improved visibility.

The following criteria should be considered for effective use of

Positive Ventilation:

- The cone of air must cover the intake opening. The fan must be placed

the correct distance from the structure such as that the cone of air

forms a seal around the opening.

- The size and location of the discharge is important. The discharge,

if at all possible should be as high and far away from the intake as is

practical. The discharge size should be between 3/4 to 1/2 times the

intake. This may not always be possible as the fire may have already

dictated discharge locations and sizes; but whenever there is a choice,

the above criteria should be used.

- It is important to control the ait flow between the intake and

discharge. Positive pressure ventilation can move air long distances if

proper control is maintained by opening and closing doors, windows,

etc. It is important that firefighters understand not to open the

structure too much: ie breaking windows, etc.

The standard features of Canada Blower Positive Pressure Ventilators

include: fold down "T" handle; 8" pneumatic tires with full width axle;

a "tilt and lock" device that allows the unit to be angled 20 degrees

up or down with infinite positions in between; sturdy and light 1 inch

wrap around frame. Explosion proof electric motors are available as

drivers too.