Canadian Blower VaneAxial Fans

Canadian Blower and Forge

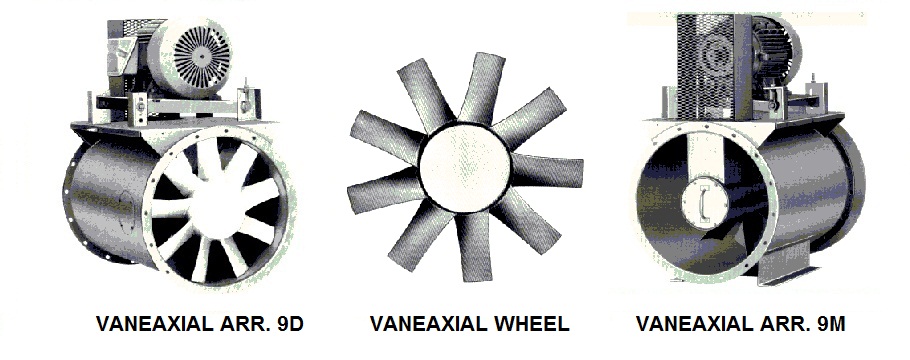

VaneAxial inline duct Fans

for variable volume air handling applications utilize adjustable pitch

high efficiency aerofoil aluminum fan propellers to provide optimum

performance.

Buffalo Type VPS Adjustax have an internal fan blade pitch adjustment,

which allows to bring variable air volume capability for air

conditioning, heating and ventilating applications.

Canada Blower VSBD vaneaxial fan

is designed for highly corrosive environments and high temperature

applications where an aluminum wheel is not suitable. Standard

construction can accommodate operation to 200°F (93°C) and can

be customized to handle up to 300°F (148°C). Steel construction

is standard on this ventilator. The VSBD fan is also available in

stainless steel.

Canada Blower VSBD's steel propellers are manufactured with a spun

steel hub. Steel fan blades are welded to the hub and can be attached

at precise angles ranging from 30° to 50°.

For applications requiring extensive corrosion resistance or operation

at higher temperatures than standard, Canada Blower Arrangement 9 VSBD

/ TSBD fan is the perfect choice. Standard Canada Blower ventilator

construction is good for operation to 200°F; fans can be customized

to handle up to 300°F. Steel fan construction is standard, all

stainless steel construction is available. Driven by either a fixed or

adjustable V-belt drive system, the exact point of fan rating can be

achieved. A future change in rating can be accomplished through a

simple sheave change.

Clamshell Design Vaneaxial Fans are used primarily in applications where ready access to the interior of the fan is desired. The entire bearing assembly can be removed quickly and easily, without removing the fan from the stack. Heavy duty pillow block anti-friction bearings with split inner cylinder are standard. Clamshell design vaneaxial fans are avaiable with steel wheels and aluminum fan wheels.

Spray Booth Design Vaneaxial Fans are available in standard belt drive arrangement 9. These fans are designed for use in spraybooth installations, or in a variety of applications where requirements make it necessary to clean the fan periodically. Standard ventilator accessories include: inlet / outlet cones, inlet bell, screensfor fan, cone, or bell; belt guard, weather proof motor and drive cover, spark resitant construction with aluminum wheels, or steel wheels with bronze tipped blades; support legs, suspension clips, shaft seals are also available as standard options.

Spark Resistant X-proof construction on tubeaxial and vaneaxial fans is available in all aluminum airstream (AMCA A) construction; aluminum wheel (AMCA B) construction; and steel wheel with bronze tipped fan blades and shaft retainer (AMCA C) construction.

High temperature fan construction: upon request Buffalo vaneaxial fans can be furnished with optional high temperature construction for oven exhaust, or combusting gases exhaust applications.

Corrosion resistant

construction and chemical duty construction:

for corrosive environment all vaneaxial fans are available in FRP

construction, as well as in 304 SS, 316 SS, or 316 L stainless steel

construction. Special coatings are optional and selection is made based

on the fan application.

http://www.tenderall.com/index.html

http://www.tenderall.com/ahu/index.html

http://www.tenderall.com/airhandler/index.html

http://www.tenderall.com/blower/index.html

http://www.tenderall.com/blowerwheel/index.html

http://www.tenderall.com/contact/index.html

http://www.tenderall.com/fanblower/index.html

http://www.tenderall.com/hvac/index.html

http://www.tenderall.com/inquiry/index.html

http://www.tenderall.com/ventilator/index.html

Engineering

Sales of Buffalo Blower / New York

blower and fans, American Coolair, ILG Chicago, Illinois Blower,

Industrial Gas

Engineering Industrial air products, fan and blower including high

temperature;

high pressure blowers and fans, pressure blowers, heavy duty industrial

process

fans and blowers. Super high temperature fans, air tight and zero

leakage

blowers and centrifugal axial fans, explosion

proof fans and ventilators. Canada Blower

Company is a Industrial regenerative pressure blowers, ILG commercial

fans, high-temperature centrifugal and axial blowers, high pressure

side channel blowers, OEM fans, roof and wall exhausters, ventilation

equipment, HVAC, heating ventilating and air-conditioning equipment,

process and O.E.M. blowers, custom built fans, ventilators, dust

collection and combustion pressure blower fans.

Canada Blower Co. offers a PT Power Tube Make-Up Air System a sone of

the most economical options for larger industrial plants ventilation

air make up.

When exhaust fans are used to provide ventilation, both for industrial

and process exhaust and personnel comfort, a negative air pressure is

created within the building. This negative pressure causes several

problems:

- Process exhaust systems are less efficient and may not work properly.

- Down flow can occur through gravity vents and result in the back

venting of products of combustionfrom flues and stacks of heaters and

process equipment.

- Drafts are created that are a dsicomfort to employees. Safe operating

of outside doors may even be impaired.

Our Power Tube Fan Make-Up Air System solves all of these problems

economically, even on the coldest winter day.

In the winter, conventional make-up air systems have to heat the cold

outside air prior to introduction into the building. This is an

expensive process in both equipment and continuing energy cost. The

Power Tube Fan Make-Up Air System is a simplier system that utilizes

wasted building heat and basic aerodynamic principles for supplying,

tempering and distributing make-up air. And that makes it less

expensive than conventional make-up air systems to purchase, to install

and to operate.

PT Power Tube Fan Make-Up Air System uses a special propeller fan with

straightening vanes and fan housing mounted to an opening in a building

sidewall near the ceiling (an optional roof mounting model is

available). A motor operated wall shutter is attached to the outside

wall opening under a protective weather hood. A long specially

constructed reinforced polyethylene tube is connected to the fan

discharge orifice to carry fresh outside air throughout the building

and temper it by mixing cold outside air with warm inside air near the

plant ceiling before it reaches floor level.

Specially sized and spaced discharge holes in the polyethylene tube

produce relatively high velocity turbulent jets of air. This turbulent

jet flow swirls and mixes surrounding air particles resulting in the

entrinment of the warm ceiling air and the complete tempering of very

cold outside air within a relatively short distance. The result is

heated make-up air at the price of unheated make-up air.

Power Tube Make-Up Air Fans are available in Sizes 18 to 48 for for air

flows up to 40,000 CFM.

PT Power Tube Make-Up Air System tube is constructed of thick woven

high density polyethylene fiber(8 x 8) laminated with poly coating to a

thickness of 6 Mils. It is 3.8 oz. per square yeard material. Burst

strength is 118 Lbs per square inch. The material is flame retardant

and complied with NFPA Standard 701. Tubes are available in two colors:

blue and white. One end of the polyethylen tube is factory dealed.

Sufficient make-up air should be provided to balance exhaust from

general ventilation and process ventilation. Usually several Power Tube

Fans will be required, located to distribute air throughout the plant.

If additional tempering of make-up air in specific plant areas becomes

necessary, unit heaters can be added.

OTHER BLOWERS AND FANS CANADA BLOWER SUPPLY:

- Combustion air supply blowers;

- Oven circulation fans;

- Pneumatic conveying blowers;

- Dust collector fans;

- Super high pressure fans;

- Material handling blowers;

- Exhaust and supply process fans.