Wall Fans manufactured by experts!

Direct-drive and belt-drive wall fan are available in centrifugal wall fan construction and axial propeller fan construction. This is an extremely quiet general exhaust, or supply ventilator fan. When supplied with filter package it is used as ambient make-up air fan. Recommended for industrial and commercial applications such as stores, laboratories, offices, agricultural green houses, warehouses, industrial buildings; and in public meeting areas such as churches, auditoriums and theatres for the removal of large volumes of air with low power output. Designed for ease of maintenance and low operating cost combined with quiet operation and low visibility. Available sizes vary from 6 to 84 inches of diameter of the fan prop. Capacity: up to 105,000 CFM. Pressure: up to 2.5 inches of WG.

Wall fans construction features a heavy gauge steel panel with steel frame supports and deep-spun venturi orifice. The Q-wheel is designed for applications where exceptionally low sound levels are required. Four and six bladed die formed fixed pitch propellers are statically and dynamically balanced and are designed for general ventilation fan applications. Cast aluminum adjustable pitch propellers are intended for industrial air ventilation applications and allow for flow adjustment.

Drive mechanism Direct drive ventilator models have propeller connected directly to the motor shaft for minimal wear and maintenance. Belt-drive fan models are equipped with standard fixed, or adjustable single and multiple belts, with variable pitch cast iron pulley for adjusting fan speed. A motor slide base allows for belt tension adjustment. Belts are oil resistant and are not static conducting. Heavy-duty pillow-block bearings with cast iron housings are self-aligning and relubricable , with zerk fittings with extended bearing lube lines. Motors are of totally enclosed (TEFC, or TEAO) type. Explosion proof motors, severy duty motors, IEEE841 motors, mill and chemical duty motors, and special motors are available upon request. All motor brands are UL and CSA certifed and serviced worldwide.

Ventilator Options and Accessories: Wall Housing / Wall Cabinet / Wall Sleeve of galvanized steel is available for convenient mounting and proper spacing of shutters. Automatic and Motor-Operated Fan Shutters are recommended for weather protection and to prevent backdraft when power supply is off. Motorized fan shutters are available for opening/closing action on all air supply applications. Safety Guards are available in motor-side configuration and blade-side configuration. Safety cage is available for total enclosing of the panel fan. All safety guards meet OSHA requirements. Special protective coatings and alloys (aluminum, or stainless) are available upon request. All wall fans have epoxy coating as a standard. Safety Disconnect Switches cut power to motor for servicing of the unit. They are mounted adjacent to fan panel. Fan speed controller provides capability to change performance and speed ranging from 0 % to 100 % of fan capacity for fine-tuning and balancing of the ventilation system.

All ventilator models wall fans

bear the

AMCA Certified Ratings Seal.

Canada

Blower centrifugal blowers have many applications including general

ventilation, those requiring high airflows, manufacturing process,

emergency or continuous high temperature, or grease-laden exhaust.

Material choices range from galvanized steel, steel with corrosion

resistant coatings, aluminum, fiberglass, or stainless steel. Designs

are tiered to provide the most economical, practical and efficient

operation by performance requirements and application.

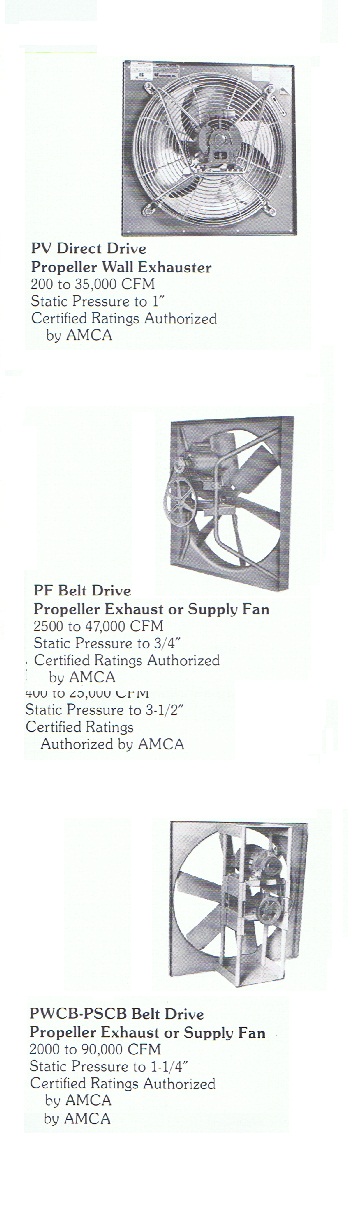

Wall mounted fans include both

direct- and belt-driven fans with various impeller types. Use

centrifugal exhaust fans for clean or contaminated air applications.

Propeller style fans are available for exhaust, supply, filtered

supply, and reversible applications.

http://canadianblower.com/0/Index.html

http://canadianblower.com/1/Index.html

http://canadianblower.com/2/Index.html

http://canadianblower.com/3/Index.html

http://canadianblower.com/4/Index.html

http://canadianblower.com/5/Index.html

http://canadianblower.com/6/Index.html

http://canadianblower.com/7/Index.html

http://canadianblower.com/8/Index.html

http://canadianblower.com/9/Index.html

http://canadianblower.com/10/Index.html

http://canadianblower.com/11/Index.html

http://canadianblower.com/12/Index.html

http://canadianblower.com/13/Index.html

http://canadianblower.com/14/Index.html

http://canadianblower.com/15/Index.html

http://canadianblower.com/16/Index.html

http://canadianblower.com/17/Index.html

http://canadianblower.com/18/Index.html

http://canadianblower.com/19/Index.html

http://canadianblower.com/20/Index.html

http://canadianblower.com/21/Index.html

http://canadianblower.com/22/Index.html

http://canadianblower.com/23/Index.html

http://canadianblower.com/24/Index.html

http://canadianblower.com/25/Index.html

http://canadianblower.com/26/Index.html

http://canadianblower.com/27/Index.html

http://canadianblower.com/28/Index.html

http://canadianblower.com/29/Index.html

http://canadianblower.com/30/Index.html

http://canadianblower.com/31/Index.html

http://canadianblower.com/32/Index.html

http://canadianblower.com/33/Index.html

http://canadianblower.com/34/Index.html

http://canadianblower.com/35/Index.html

http://canadianblower.com/36/Index.html

http://canadianblower.com/37/Index.html

http://canadianblower.com/38/Index.html

http://canadianblower.com/39/Index.html

http://canadianblower.com/40/Index.html

http://canadianblower.com/41/Index.html

http://canadianblower.com/42/Index.html

http://canadianblower.com/43/Index.html

http://canadianblower.com/44/Index.html

http://canadianblower.com/45/Index.html

http://canadianblower.com/46/Index.html

http://canadianblower.com/47/Index.html

http://canadianblower.com/48/Index.html

http://canadianblower.com/49/Index.html

http://canadianblower.com/50/Index.html

http://canadianblower.com/51/Index.html

http://canadianblower.com/52/Index.html

http://canadianblower.com/53/Index.html

http://canadianblower.com/54/Index.html

http://canadianblower.com/55/Index.html

http://canadianblower.com/56/Index.html

http://canadianblower.com/57/Index.html

http://canadianblower.com/58/Index.html

http://canadianblower.com/59/Index.html

http://canadianblower.com/60/Index.html

http://canadianblower.com/61/Index.html

http://canadianblower.com/62/Index.html

http://canadianblower.com/63/Index.html

http://canadianblower.com/64/Index.html

http://canadianblower.com/65/Index.html

http://canadianblower.com/66/Index.html

http://canadianblower.com/67/Index.html

http://canadianblower.com/68/Index.html

http://canadianblower.com/78/Index.html

http://canadianblower.com/79/Index.html

http://canadianblower.com/80/Index.html

http://canadianblower.com/81/Index.html

Quick delivery of portable

ventilation blowers, ventilating fans,

industrial centrifugal exhaust fans, heavy duty exhaust ventilators,

duct fan blowers, high pressure pressure blowers, restaurant kitchen

exhaust fans UL762 / UL705, squirrel cage ventilators, garage exhaust

fans, dust collection fans, shop exhaust ventilators, blow off pressure

blowers, fune exhaust fans, ventilator blades, oven ventilators.

Industrial & OEM fans, blowers, ventilators, pressure blowers and

high temperature fans. Sales of centrifugal & axial fans and

blowers, industrial process fans, building ventilators, dust collecting

fans. Supplier of radial blowers, vaneaxial & tubeaxial

ventilators, explosion proof spark-resistant fans, fiberglass FRP, PVC

and Propylene blowers, oven circulating super high temperature fans.

Designers of air tight sealed blowers, stainless steel, aluminum and

special alloy fans, super high pressure centrifugal, regenerative, side

channel and multi-stage blowers, high volume ventilators. Engineering

of air moving and industrial ventilation equipment, combustion blowers,

material handling and pneumatic conveying fans, inline direct &

belt driven ventilators. Distributors of Chicago Blower, American

Coolair / ILG NYB TCF fans, wall & roof exhaust and supply power

ventilators, panel propeller fans, gas-fired direct and indirect

make-up air handling units AHU, air curtains and blow-off air knives

and air-knife systems, fan silencers, corrosion-resistant ventilators,

positive pressure ventilators, mobile macoolers, reversible duct

ventilators, fan dampers and louvers.

Explosion

proof backwardly

inclined; airfoil; radial and radial-tip

fans and blowers. Pressure blowers; plug

fans; air kits; centrifugal and axial ventilators.

Power generation units, chemicals, textile mills, cement, pharmaceuticals, oil and petroleum refineries, hotels, fertilizers, and other major industries that contribute significantly to the economy on a national level depend heavily on axial flow fans. These fans are designed with impellers, which is a series of fan blades. Typically, the impellers are made from aluminum or mild steel, which is strong and durable.

The challenge is choosing the right aerofoil and metallic blower impellers that offer dimensional stability. Choosing the wrong impellers often leads to a greater consumption of power and a higher level of noise pollution without lesser levels of efficiency. Fortunately, people can always turn to Fiber Reinforced Plastic fans or FRP fans.

For higher energy levels, fan manufacturers around the world have considered using fiberglass reinforced plastic axial fans. With a more advanced design, these fans produce higher drag and lift ratio. Therefore, the overall efficiency is dramatically improved. The improved aerodynamic design provides numerous benefits that go hand in hand with FRP fans, including higher productivity and better quality.

Key Advantages of FRP Fans:

When it comes to Fiber Reinforced Plastic fans or FRP fans, there are several key benefits. Because of that, these fans are ideal for both industrial and commercial HVAC applications.

Aerodynamic Impellers For one thing, FRP fans have impellers that are aerodynamically designed. Therefore, the fans produce a higher efficiency that makes them perfect for a broader range of ventilation applications.

Weight Reduction Another benefit associated with FRP fans is that when compared to other types of fans, there is a noted reduction in weight. Not only does this enhance durability, it actually helps extend the life of the mechanical drive systems, including motors, bearings, gear boxes, and more.

Systems and Ratings FRP fans only need light-duty bearing systems, as well as lower drive motor ratings.

Less Power Consumption To operate FRP fans, less power consumption is required. Ultimately, this saves on energy, especially when making a comparison to other metallic-type fans.

Fabrication Manufacturers of Fiber Reinforced Plastic fans use composite fabrication procedures, such as resin transfer molding, standard molding, and compression. As a result, the fans boast a consistent quality and the dimensions of the impellers are uniform.

Noise Pollution One advantage of FRP fans that people appreciate is the reduced amount of mechanical noise and flow sound. As imagined, this makes the working environment more enjoyable as well as safer from a hearing perspective.

Durability and Lifespan Due to their enhanced mechanical strength, FRP fans are more durable, and they have a longer lifespan.

Corrosion Resistance Because of the materials used in manufacturing fiberglass reinforced plastic fans, they are more resistant to erosion and corrosion.

Fire Safety Fiberglass reinforced plastic fans produce vibration-free operation, and they are fire retardant.

.

.