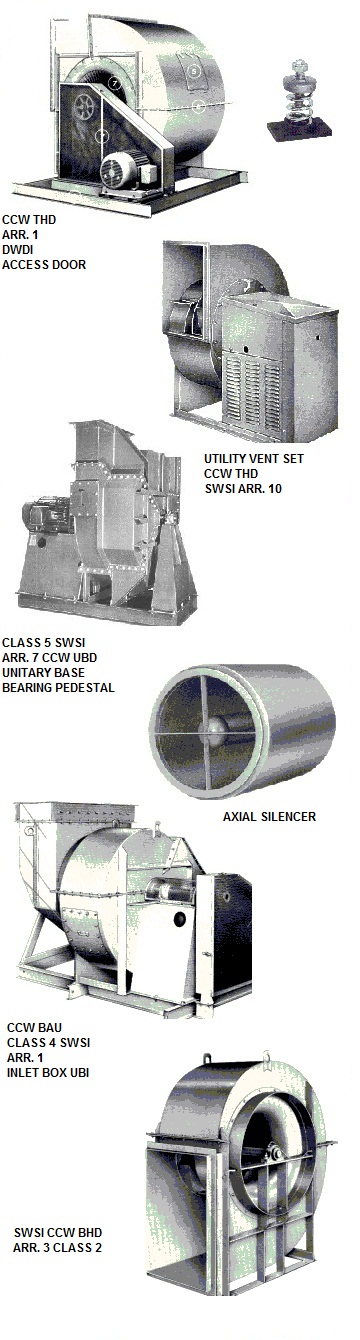

Industrial high pressure heavy

duty centrifugal fans, blowers, ventilators. Sales of scroll cage

centrifugal and radial bladed pressure blowers, high temperature

centrifugal and axial fans.

Centrifugal blower has a number of blades mounted around the hub, which turns on a shaft that passes through the housing.

A Centrifugal fan can come in three different types of fan blades. They can come with forward curved blades, backward curved blades and straight radial blades. The type you need will come down to what the conditions are within the area in which you intend to use the device.

Canada Blower Square Direct Drive Centrifugal Fans combine the performance and efficiency of Canada Blower's versatile "Square" fans with the advantages of a compact directly driven arrangement. With the fan wheel mounted directly onto motor shaft maximum efficiency is constantly maintained. Belt noise, power loss, maintenance and troublesome adjustments are eliminated.

Canada Blower's Direct Drive Fan is available with both airfoil and flat blade backwardly inclined wheels. With the choice of two types of wheels application duty can be matched precisely. Also, the different performance characteristics of the two fan wheels allow for a wider performance range at standard synchronous motor speeds. The compact SQAD / SQBD fans are used in diverse OEM applications, from packaged forced air and dust collection systems to pressurizing and aeration installations.

The proficiency gained as a leading supplier of industrial and custom heavy-duty fans is reflected in the rugged constructionof all Canada Blower built fans. It's called "Industrial Quality" and guarantees exceptional performance and reliability.

When inquiring about purchasing a centrifugal fan you will more than likely need someone from the company in which your purchasing the fan to come and take a look at the conditions the fan will be placed and also to check what kind of air pressure there is within the area.

The size of the area in which the centrifugal blower is to be used will obviously play a major part in the decision of how large it needs to be and how much air it can actually blow through the area. There are many different sizes that you can get to cover any area but depending on your circumstances you may need more than one to do the job adequately.

The type of air that is in the premises will also play a large role in which type of Centrifugal Blower you need. If the centrifugal fan is to be used in an area where the air conditions are standard then no adjustments will need to be made to the actual fan itself. On the other hand if you are going to operate the fan in other types of air density then adjustments can be made to the static pressure and brake horsepower.

Engineering of Twin City Aerovent fans, CBC Chicago Blower fans, Acme fan ventilators, New York Blower, ILG American Coolair fans, fans for building ventilation, industrial high temperature oven fans, furnace blowers, leader ventilators, Delhi fans, negative pressure ventilators, USA industrial fas blowers, explosion proof pressure blowers, blower air knives, high temperature pressure blowers.

Canada Blower Company fans are well know for their highest manufacturing quality, reliability and industrial toughness for many years across the world.

Regenerative blowers operate as a multistaged compressors. Each blade-to-blade regeneration stage results in a slight pressure increase. Total pressure rise from air entry to discharge yields a continuous operating pressure up to 300-in. w.g. (11 PSIg) or a vacuum to 14-in. Hg with continuous flows to more than 1400 scfm (Fig. 3).

Regenerative blowers are ideal for moving large volumes of air at low pressures or vacuums. Unlike positive displacement compressors and vacuum pumps, they pressurize air through a nonpositive displacement method. Typical regenerative blower applications include sewage aeration, vacuum lifting, vacuum packaging, pneumatic conveying, concrete aeration, pond aeration, vacuum tables, drying, dust/smoke removal, air sparging, and chip removal.

Of all air handling equipment, regenerative blowers are probably the least understood. However, when system parameters fall within their range, they can be among the most cost-effective methods for moving air and producing pressure or vacuum.

Regenerative blowers are sometimes called side channel blowers or ring compressors, terms that refer to their physical construction. They can be direct or belt driven. In direct drives, the impeller is mounted on an electric motor shaft. The number, size, and angle of the blades on the impeller determine pneumatic performance as well as the relationship between the impeller and housing. Some blowers have rather flat performance curves while others have steep ones.

The impeller spins within a housing with an inboard and outboard channel. It is from this configuration that the name side channel blower is drawn. As the impeller blades pass the inlet port, they draw air in. The impeller rotation pushes air outward and forward into the channels. The air then returns to the base of the blade. As the impeller spins, the process repeats. This regeneration gives the blower its pressure/vacuum capabilities.

Most blowers are single stage: Air travels around the blower housing once and is discharged. Two-stage regenerative blowers can provide almost twice the pressure or vacuum of single-stage units. In a single-impeller, two-stage unit, air makes one revolution around the front side of the impeller. Then, instead of being discharged, the air is channeled to the backside of the impeller through internal porting. Air then makes another revolution around the backside of the impeller before it is discharged. Other two-stage configurations are also available, including designs that use two separate impellers in one housing or two impellers and housings.

Among the major benefits of a regenerative blower is its lack of maintenance and monitoring requirements. The impeller is the only moving part and is wear free and does not come in contact with the housing channels. Self-lubricated bearings are the only parts that wear.

Regenerative blowers are oilless and have no complicated intake/exhaust valving. Most can be mounted in any plane and, with dynamically balanced impellers, generate little vibration. Because they are nonpositive displacement compressor/vacuum pumps, they discharge air that is clean and pulsation free, which are important considerations for today's plant instruments and controls.

The majority of blower failures are caused by improper installation or operation. Regenerative blowers have close internal clearances between the impeller and housing. It is important to prevent foreign material from entering that space. Ingested debris wedging between the impeller and housing can cause the blower to lock up and lead to a catastrophic failure. A blower should always be equipped with an intake filter. A 10-micron size is usually adequate. Filters must be kept clean. A blocked filter will starve flow.

Centrifugal blower has a number of blades mounted around the hub, which turns on a shaft that passes through the housing.

A Centrifugal fan can come in three different types of fan blades. They can come with forward curved blades, backward curved blades and straight radial blades. The type you need will come down to what the conditions are within the area in which you intend to use the device.

Canada Blower Square Direct Drive Centrifugal Fans combine the performance and efficiency of Canada Blower's versatile "Square" fans with the advantages of a compact directly driven arrangement. With the fan wheel mounted directly onto motor shaft maximum efficiency is constantly maintained. Belt noise, power loss, maintenance and troublesome adjustments are eliminated.

Canada Blower's Direct Drive Fan is available with both airfoil and flat blade backwardly inclined wheels. With the choice of two types of wheels application duty can be matched precisely. Also, the different performance characteristics of the two fan wheels allow for a wider performance range at standard synchronous motor speeds. The compact SQAD / SQBD fans are used in diverse OEM applications, from packaged forced air and dust collection systems to pressurizing and aeration installations.

The proficiency gained as a leading supplier of industrial and custom heavy-duty fans is reflected in the rugged constructionof all Canada Blower built fans. It's called "Industrial Quality" and guarantees exceptional performance and reliability.

When inquiring about purchasing a centrifugal fan you will more than likely need someone from the company in which your purchasing the fan to come and take a look at the conditions the fan will be placed and also to check what kind of air pressure there is within the area.

The size of the area in which the centrifugal blower is to be used will obviously play a major part in the decision of how large it needs to be and how much air it can actually blow through the area. There are many different sizes that you can get to cover any area but depending on your circumstances you may need more than one to do the job adequately.

The type of air that is in the premises will also play a large role in which type of Centrifugal Blower you need. If the centrifugal fan is to be used in an area where the air conditions are standard then no adjustments will need to be made to the actual fan itself. On the other hand if you are going to operate the fan in other types of air density then adjustments can be made to the static pressure and brake horsepower.

Engineering of Twin City Aerovent fans, CBC Chicago Blower fans, Acme fan ventilators, New York Blower, ILG American Coolair fans, fans for building ventilation, industrial high temperature oven fans, furnace blowers, leader ventilators, Delhi fans, negative pressure ventilators, USA industrial fas blowers, explosion proof pressure blowers, blower air knives, high temperature pressure blowers.

Canada Blower Company fans are well know for their highest manufacturing quality, reliability and industrial toughness for many years across the world.

Regenerative blowers operate as a multistaged compressors. Each blade-to-blade regeneration stage results in a slight pressure increase. Total pressure rise from air entry to discharge yields a continuous operating pressure up to 300-in. w.g. (11 PSIg) or a vacuum to 14-in. Hg with continuous flows to more than 1400 scfm (Fig. 3).

Regenerative blowers are ideal for moving large volumes of air at low pressures or vacuums. Unlike positive displacement compressors and vacuum pumps, they pressurize air through a nonpositive displacement method. Typical regenerative blower applications include sewage aeration, vacuum lifting, vacuum packaging, pneumatic conveying, concrete aeration, pond aeration, vacuum tables, drying, dust/smoke removal, air sparging, and chip removal.

Of all air handling equipment, regenerative blowers are probably the least understood. However, when system parameters fall within their range, they can be among the most cost-effective methods for moving air and producing pressure or vacuum.

Regenerative blowers are sometimes called side channel blowers or ring compressors, terms that refer to their physical construction. They can be direct or belt driven. In direct drives, the impeller is mounted on an electric motor shaft. The number, size, and angle of the blades on the impeller determine pneumatic performance as well as the relationship between the impeller and housing. Some blowers have rather flat performance curves while others have steep ones.

The impeller spins within a housing with an inboard and outboard channel. It is from this configuration that the name side channel blower is drawn. As the impeller blades pass the inlet port, they draw air in. The impeller rotation pushes air outward and forward into the channels. The air then returns to the base of the blade. As the impeller spins, the process repeats. This regeneration gives the blower its pressure/vacuum capabilities.

Most blowers are single stage: Air travels around the blower housing once and is discharged. Two-stage regenerative blowers can provide almost twice the pressure or vacuum of single-stage units. In a single-impeller, two-stage unit, air makes one revolution around the front side of the impeller. Then, instead of being discharged, the air is channeled to the backside of the impeller through internal porting. Air then makes another revolution around the backside of the impeller before it is discharged. Other two-stage configurations are also available, including designs that use two separate impellers in one housing or two impellers and housings.

Among the major benefits of a regenerative blower is its lack of maintenance and monitoring requirements. The impeller is the only moving part and is wear free and does not come in contact with the housing channels. Self-lubricated bearings are the only parts that wear.

Regenerative blowers are oilless and have no complicated intake/exhaust valving. Most can be mounted in any plane and, with dynamically balanced impellers, generate little vibration. Because they are nonpositive displacement compressor/vacuum pumps, they discharge air that is clean and pulsation free, which are important considerations for today's plant instruments and controls.

The majority of blower failures are caused by improper installation or operation. Regenerative blowers have close internal clearances between the impeller and housing. It is important to prevent foreign material from entering that space. Ingested debris wedging between the impeller and housing can cause the blower to lock up and lead to a catastrophic failure. A blower should always be equipped with an intake filter. A 10-micron size is usually adequate. Filters must be kept clean. A blocked filter will starve flow.