CEILING FANS manufactured by experts!

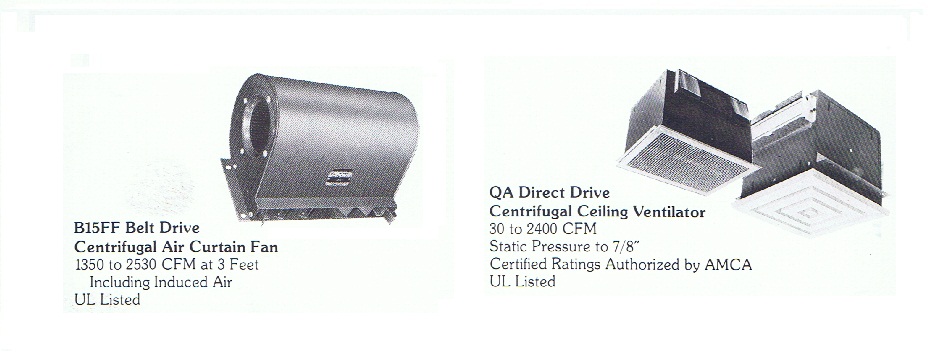

Ceiling Exhauster, or Ceiling Fans are specifically designed for installation above ceilings and in remote locations in today’s modern buildings. Ceiling fans are available as Ceiling Exhausters, Inline Exhausters and Cabinet Fans

Ceiling Fan, Ceiling Exhauster, In-Line Exhauster, and Cabinet Fan Construction: Ceiling fan housing is lined with special sound absorbing glass fiber for maximum sound attenuation. Fan housing have adjustable brackets or easy mounting. Dynamically balanced squirrel cage aluminum centrifugal impeller insures quiet, and highly efficient operating levels. Rubber motor mounts isolate motor vibration. Ventilator motors are permanently lubricated with overload protection. Most fans are shipped from factory in horizontal discharge position. Horizontal, or Vertical discharge are standard options. Attractive molded white plastic square and rectangular grills and aluminum grills with baked enamel finish are supplied with all ceiling fans. Build-in dampers cut off the back-draft. As standard units are shipped with right angle discharge. When in-line mode is required access panel and duct flange are easily removable for remounting in the field to switch to IL In-Line arrangement.

Ceiling Fan, Ceiling Exhauster, In-Line Exhauster, and Cabinet Fan Accessories Solid state Controllers provide an infinite number of motor speeds. Thus the need of 2- and 3-speed motors is eliminated completely in the new line of ceiling fans. Roof Jack is supplied with built-in back-draft damper and bird screen. It provides waterproof outlet for sloped roofs. Wall Cap is an all-weatherproof wall outlet. It is also supplied with built-in back-draft fan damper and it is available in bonderized steel and baked enamel finish over aluminum base. Eave elbows are designed for under eave discharge. Built-in back-draft fan damper and outlet grille provided with each unit. Vent Caps are intended for roof mount on sloped, or flat roofs. Available in all aluminum construction with mesh galvanized bird screen. In-line adaptor plates provide an inexpensive method for mounting both intake and outlet to duct work of the same size. Grille is discarded and the adaptor plate is used on the fan side.

Ceiling Fan, Ceiling exhauster, Inline exhauster, and

Cabinet Fan applicatios

Ceiling fans are designed for use as exhaust fans for all types of

commercials and administartive buildings predominantly for indoor

applications.

The main objectives of Canada Blower laboratory exhaust system

are removing hazardous or noxious fumes, diluting the fumes, and

expelling them at high velocity from the building to minimize the

possibility of roof area contamination or re-entrainment into the

building make-up air system. Vektor® systems safely discharge lab

exhaust in life-safety applications. The high plume nozzle and dilution

windband entrain outside ambient air to assist in the increased

dilution of laboratory exhaust while maintaining effective plume

height. Higher nozzle velocity creates a higher dilution, diluting and

dispersing potentially hazardous exhaust or fumes quickly and safely.

The Variable Geometry Nozzle (VGN) automatically adjusts to maintain

the specified discharge velocity as airflow varies. This safely

prevents re-entrainment in the make-up air unit. The VGN provides

energy savings in reduced lab flow situations without introducing

bypass air to maintain ANSI required outlet velocities.

All models wall fans bear the AMCA Certified Ratings Seal.

http://tenderall.com/index.html

http://tenderall.com/ahu/index.html

http://tenderall.com/airhandler/index.html

http://tenderall.com/blower/index.html

http://tenderall.com/blowerwheel/index.html

http://tenderall.com/contact/index.html

http://tenderall.com/fanblower/index.html

http://tenderall.com/hvac/index.html

http://tenderall.com/inquiry/index.html

http://tenderall.com/ventilator/index.html

Sale of TCF NYB fans / blowers, American Coolair ventilators, Aerovent ventilators / fans, side channel blowers, regenerative blowers, Canarm ventilators, ACME fans, Leader Delhi fans, ILG ventilators, Plastec propylene blowers, New York Ventilators, confined space fans and ventilators.

Suppliers of industrial regenerative side channel blowers, forward curved pressure blowers and fans in stainless steel, alloy, cast aluminium, cast iron, polypropylene and FRP construction. Canadian Blower, Chicago supplies replacement forward curved blowers and wheels for forward curved blowers and fans manufactured by Buffalo Blower - New York, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian blower, Aerovent, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Breidert, Anderson 2000, Solar and Palau, Strobic air, Trane, TCF Axial.

Canada Blower Company is a Distributor of industrial process and commerical ventilation equipment. Canada Blower fans are known for the highest industrial duty quality and reliability for many years across North America.

In many dryer applications, the static pressure requirement is between 0.5 and 3" 0f water column. For these pressure requirements, a duct vaneaxial fan often is the best selection. The duct vaneaxial fan offers a broad performance range and good pressure capability at high static efficiency. It also offers the benefit of placing the bearings, shaft and drives on the negative pressure side of the propeller. This setup draws ambient air across those components during operation and discharges it into the hot moist air. This fan also can be provided with a shaft seal to further isolate the components or high temperature construction for operation up to 500 deg. F (260 deg C).

Fan performance tables are based on standard air. Selecting a fan using standard tables will provide a fan capable of moving the required flow and developing the required pressure. As the temperature increases and humidity decreases, system resistance and the pressure developed by the fan will decrease at the same rate, and a constant flow rate is maintained. Altitude reduces the air pressure and density along with the amount of moisture the air can carry. The density and moisture values in table 1 must be divided by the correction factors in table 4 to determine the actual density and mois-ture content per cubic foot.

Divide density and moisture values by altitude correction factors to determine actual density and moisture.

For higher pressure ranges, a backward curved centrifugal fan often is selected. This design offers pressures up to 20" water gauge. They also offer the benefit of having the shaft and bearings outside the fan, and they can be mounted on the roof with a weather cover.

As with all fan systems, it is important to remember that only available air can be exhausted. Fans cannot operate in a vacuum. If the exhausted air cannot be replaced in the facility, fan performance will drop off and production will suffer. The production facility must have makeup air for every cubic foot that is exhausted from the facility. The makeup air can be provided through general ventilation systems or as part of a heating, ventilating and air conditioning system.

With the exhaust requirements calculated and fan system sized to handle the required volume at the required pressure, the drying process will run smoothly. Production results are consistent and the production facility's environment also is improved by removing contaminated air. A good understanding of exhaust requirements allows better control of the drying process..