Supplier of regenerative blowers, positive displacement blowers, Acme fans, Delhi fans, fiberglass fans / FRP blowers, Plastec Propylene fan ventilators, American Coolair ILG ventilators & fans, Grainger ventilators, explosion proof blowers, power roof ventilators, replacement fan bldes / blower wheels. New York Blower fans and blowers: high pressure fans, high temperature blowers, general ventilation utility fans, centrifugal and axial fans and ventilators.

Buffalo Blower industrial high temperature pressure blowers, high pressure fans, high volume industrial pressure blowers. Sales of Canadian Blower pressure blowers.

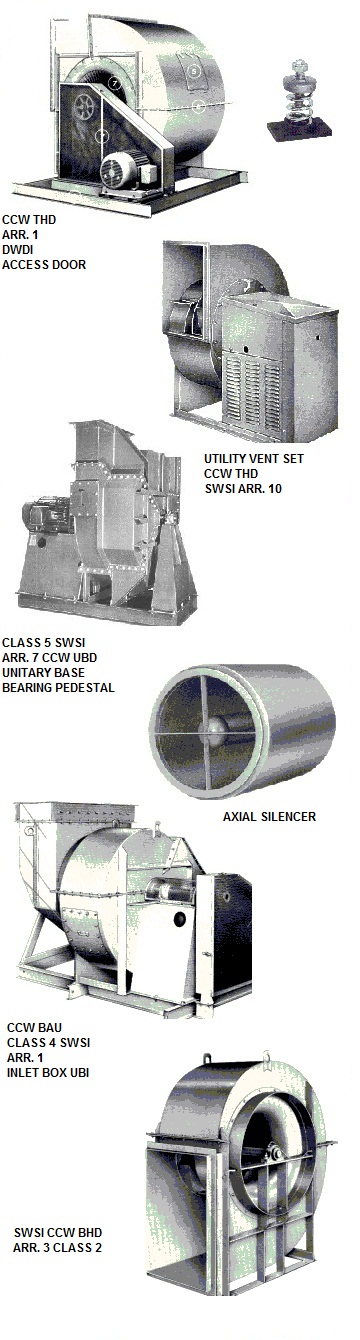

Industrial backward inclined (BI) fan blower

SWSI,

DWDI, AcF, PLR, BI, BC, AF, ST, Backward Inclined Fans, Aerocline,

General

Purpose, GP, BL, Limit Load, LL, Buffalo Vent Set, BCV, BCA, BCM, BCS:

industrial backward inclined blowers supplied in welded heavy gauge

steel construction to prevent flexing at high pressure. Available in

direct drive arrangements 4/4V/4H/7/8 and belt drive arrangements

1/3/9/10. Arr. 10 blowers are known as ventilating fan sets (vent

sets).

Available in single width single inlet (SWSI), or double width double

inlet (DWDI) ventilators wheels. Capacities: to 500,000 CFM. Static

pressure up to 100

inches water gauge depending on the class of construction. Typical

class of construction is Class 1, 2, 3, 4, 5.

Aluminum wheel, Steel wheel, or Alloy wheel: industrial backward inclined (bi) blowers and fans are supplied with aluminum fan wheel or corten wheel to meet requirements of AMCA A, and AMCA B spark resistant construction. Mild steel ventilator wheels are of all welded construction. If higher pressure is required wheel can be furnished of high strenght steel. Stainless steel wheel in 304 SS, 316 SS, 316 SS, 2205 SS are supplied for corrosive applications, or high temeparature fan applications. The pressure curve remains stable to the right of the pick point.

Inlet flanges, outlet flanges, companion fan flanges: continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern.

Shaft seal and low leakage fan construction: shafting is straightened to close tolerance to minimize "run-out" and ensure smooth operation. Teflon shaft seal, ceramic fan shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing is provided for low leakage construction and for high temperature construction.

Heat fan construction up to 800 F: includes high temperature paint, shaft cooler, shaft-cooler guard, and steel fan wheel, or alloy wheel.

Cladding for sound attenuation and silencers: cladding consists of 2 inches mineral-wool insulation covered with a welded steel jacket. As an inexpensive alternative is offered slide-on acoustic cloth jackets. Inlet silencer / outlet fan silencer are supplied with matching flanges for further attenuation of the noise level.

Inlet filter assemblies: cell type, 1 inch, or 2 inch filters are available with filter cabinet to be mounted at fan inlet. Bird guard, insect screen and weather hood are optional accessories with blower's inlet filter package.

Standard accessories:flash / raised access door, inspection port, drain and plug, unitary base, shaft and bearing guard, belt guard, motor cover, spring vibration isolation, rubber-in-share (RIS) vibration isolation, vibrating pads, outlet damper, inlet vane damper, external inlet vane damper, electrical / pneumatic actuators.

Controls and drives:

variable frequency drives (VFD), across-the-line starters, RTDs,

pressure sensors, flowmeters - complete control packages.

http://industrialfanblower.net/Index.htm

http://industrialfanblower.net/cbd_about_us.htm

http://industrialfanblower.net/contact.htm

http://industrialfanblower.net/cbd_feedback.htm

http://industrialfanblower.net/cbd_links.htm

http://industrialfanblower.net/cbd_products_heavy.htm

http://industrialfanblower.net/cbd_products_std.htm

http://industrialfanblower.net/cbd_services.htm

http://industrialfanblower.net/cbd_site_map.htm

Canada Blower Company is a distributor of all types industrial process and OEM fans and blowers, including heavy-duty fans.world.

Canada Blower Direct Drive BI Fans:

- Complete AMCA Class I, II, & III fan performance;

- Airflows to 100,000 CFM @ 25" WG;

- Efficiencies beyond 85 % due to unique blower impeller design;

- Temperatures to 750 F with heat fan construction;

- Choice of airfoil or flat backward inclined fan wheels;

- 17 sizes: 10" through 73" ventilator diameters;

- Heavy-gauge welded construction provides fan structural strenght & durability;

- Variety of fan accessories available: spark-resistant, explosion-proof and high temperature construction, dampers, shaft seals, flanges, inlet box, split housing, special coatings..

Canada Blower General Ventilating Fan Sets:

Convenience and economy of packaged Canada Blower fans design with heavy-gauge quality construction that ensures smooth operation through the Class II performance range. Canada Blower Utility Fan Sets are fully suited to industrial plant ventilation and process air needs as well as commercial and institutional ventilation service.

connectors, reducers.

Canada Blower Backward Inclined Fan is a rugged multi-purpose centrifugal fan equipped with Backward Inclined wheels suited for harsh duty applications. With heavier fan blades to resist erosion and corrosion, Canada Blower Backward Inclined Fan provides reliable operation in contaminated air with minimal maintenance. Similar BI wheels are used in Canada Blower's SQB fans for alternate duty applications. For clean airstreams, Canada Blower airfoil bladed fans are recommended. Canada Blower's backward inclined fan blades are designed to handle corrosive or dusty airstreams. Typical applications include oven circulators, dust collectors, fume exhausters and emission control systems. Canada Blower Backward Inclined Fan is also suited for high 800°F. The solid steel blades are ideal for custom applied corrosion resistant coatings.

Canada Blower Co. is a major supplier of fans and blowers for Pulp and Paper Industry.

The paper manufacturing industry utilizes fans for power boilers, recovery boilers, lime kilns, dissolving tanks, and dryers. These applications, which are integral to the production process, are often very corrosive. Reliability and durability of fans and blowers for such applications are vital for continuous operation. Canada Blower fans for demanding and corrosive applications offer real value - saving on future downtime and maintenance costs.

BOILERS

Boiler fans create efficient combustion by supplying a consistent and reliable air flow. Induce Draft Fans (I.D. Fans) operate at elevated temperatures and draw the air stream through the combustion chamber, then push it through pollution control equipment. Forced Draft (F.D. Fans) or Combustion Air Fans push the air stream into the boiler combustion chamber. Multi-Fuel Burning Power Boilers are used to create steam for different power needs. Induced Draft Fans are typically AMCA arrangement 3, single or double inlet with inlet box(es). Wheels often require abrasion resistant construction with radial tip or backwardly curved blades. Combustion Air FD Fans are typically constructed of carbon steel, and utilize airfoil or backward inclined blade design. Common AMCA arrangements for combustion air fans are arrangement 3 and 8, both with inlet vane or outlet damper control.

EXHAUST FANS

Exhaust Fans are typically used on the suction side of a scrubber or fabric filter, and pull the air / gas stream through the piping and cleaning device. Dissolving tanks are used in conjunction with Recovery Boilers to recapture process chemicals. Exhaust Fans draw hydrogen sulfide or sulfuric acid fumes through a wet scrubber. This corrosive atmosphere can require either FRP, stainless steel or alloy construction. Exhaust fans can be in either belt or direct drive arrangements. Lime Kilns may be used to recover lime used in paper manufacturing. The fans used in this process often require high pressure and handle corrosive gas streams. Straight radial or radial tipped blade designs, 304L or 316L stainless steel construction and special shaft seals are often employed.

DRYERS

Many dryers are used in the paper manufacturing process. These drying applications utilize fans extensively. Most of these applications are not extremely demanding on the fan equipment - except the Yankee Dryers that are used for the manufacturing of tissue, and require a rugged fan design to handle high temperature (up to 800 F) and pressure requirements. Arrangement 8 direct driven fans allow for access and maintenance of fan components. Accessories often include labyrinth or lip type shaft seals, insulated housings or thermal blankets, raised access doors, shaft cooling wheel and safety guards..